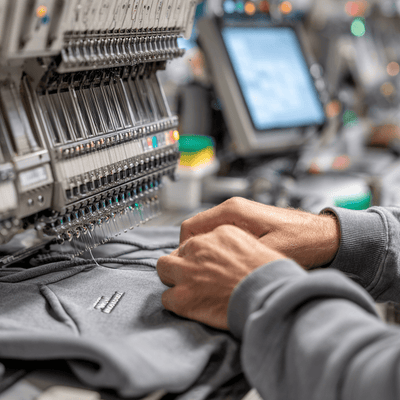

Embroidered Sweatshirts for Brands: Techniques & Production Guide

The Strategic Role of Embroidered Sweatshirts in Brand Collections

In the hierarchy of branded apparel, embroidered sweatshirts occupy a unique position—more substantial than t-shirts yet more versatile than structured outerwear. They serve as canvas pieces that balance comfort with intentional design, making them foundational items for collections across streetwear, corporate wear, and lifestyle brands. Embroidery elevates the basic sweatshirt from generic merchandise to a considered brand artifact, carrying connotations of craftsmanship and permanence that resonate with today's quality-conscious consumers. This guide addresses brand founders, creative directors, and designers actively developing sweatshirt collections, focusing on how specific embroidery techniques, strategic placement, and design execution can amplify brand identity and drive commercial success.

Unlike hoodies with their inherent sportswear associations, sweatshirts—particularly crewneck silhouettes—offer broader styling versatility and demographic appeal. The commercial search for "embroidered sweatshirts" and "custom sweatshirts" represents brands seeking to translate identity into wearable products with lasting impact. We'll analyze design trends from minimalist monograms to elaborate pictorial embroidery, break down the technical execution of each technique, and provide a production roadmap for integrating embroidery into your collection development. Understanding these elements is crucial whether you're launching a capsule collection, creating branded merchandise, or establishing signature styles for retail. For technical manufacturing processes applicable to both sweatshirts and hoodies, refer to our comprehensive guide on How Custom Hoodie & Sweatshirt Embroidery Is Made.

Design Language: How Embroidery Style Communicates Brand Personality

The aesthetic approach to your embroidered sweatshirt design establishes immediate brand perception:

Minimalist & Typographic Embroidery

- Visual Character: Clean fonts, subtle monograms, discreet logos in fine satin stitches. Often placed on left chest or sleeve.

- Brand Alignment: Sophisticated, heritage-focused, or quality-first brands emphasizing subtlety over statement. Appeals to audiences valuing timeless design and craftsmanship.

- Technical Requirement: High-precision digitizing for small text legibility and balanced stitch density.

Classic Crests & Badge Designs

- Visual Character: Circular, shield, or patch-style designs incorporating text, icons, borders, and symbolic elements. Vintage sportswear and workwear influences.

- Brand Alignment: Brands building community, tradition, or membership associations. Ideal for universities, clubs, breweries, and heritage-inspired labels.

- Technical Execution: Often combines multiple stitch types and may incorporate appliqué techniques for color fields.

Pictorial & Illustrative Embroidery

- Visual Character: Detailed images, landscapes, mascots, or complex graphics converted to stitch patterns. Ranges from nature motifs to custom illustrations.

- Brand Alignment: Storytelling brands, artistic communities, or labels with strong graphic identities. Effective for creating signature pieces that transcend basic branding.

- Technical Consideration: Requires expert digitizing to translate detail into stitch layers without losing clarity. Size and placement dramatically affect impact.

Abstract & Textural Approaches

- Visual Character: Focus on shapes, patterns, and the physical texture of embroidery itself. Uses varied stitch directions, 3D puff, or experimental techniques.

- Brand Alignment: Forward-thinking, fashion-forward labels prioritizing tactile experience and unique aesthetics over literal representation.

- Production Note: Leverages advanced embroidery capabilities to make technique part of the design narrative.

Embroidery Technique Deep Dive: Matching Method to Design Intent

Flat Embroidery (Standard Commercial Grade)

- Process: Thread covers areas with satin stitches (glossy, for borders/text) or fill stitches (tightly packed for fields).

- Best Applications: Most logos, typography, designs requiring clean color fields and professional finish. Offers maximum detail clarity.

- Commercial Considerations: Most cost-effective for standard designs, efficient production time.

3D Puff Embroidery

- Process: Foam underlay placed beneath stitches expands during steaming, creating dimensional elevation.

- Best Applications: Making key design elements (bold letters, outline shapes) stand out physically. Adds premium tactile dimension.

- Commercial Considerations: 30-50% additional cost versus flat embroidery, less suitable for fine detail.

Appliqué Embroidery

- Process: Pre-cut fabric pieces stitched onto garment with satin-stitch borders. Interior is fabric, not thread.

- Best Applications: Large solid-color areas within designs. Faster production than fill-stitching large areas.

- Commercial Considerations: Introduces mixed materials, efficient for specific color-block designs.

Chain Stitch & Specialty Techniques

- Process: Specialized machines creating vintage, hand-crafted texture or incorporating sequins/beads.

- Best Applications: Heritage aesthetics, fashion-forward detailing, or decorative embellishment.

- Commercial Considerations: Higher cost, specialized equipment, longer production times.

Strategic Placement & Scaling for Commercial Impact

Placement decisions affect wearability, visual balance, and production considerations:

- Left Chest (Standard Commercial): Classic, subtle branding. Standard for corporate collections and understated aesthetics.

- Center Chest (Statement Positioning): Bold, graphic focus. Works with larger designs or as primary collection branding.

- Sleeve/Shoulder (Secondary Accent): Complements primary branding. Athletic and teamwear influence.

- Full Back (Maximum Impact): Statement pieces for large designs, crests, or illustrative scenes. Requires stable fabric area.

- All-Over/Distributed (Pattern Effect): Multiple embroideries creating custom patterns. High production complexity.

Scaling Principles for Production

- Chest Designs: Optimal 3-4 inches width for visual balance.

- Back Designs: Scale according to garment size, typically 10-12 inches width.

- Detail Preservation: Complex designs lose clarity when scaled down below 2 inches.

- Placement Coordinates: Technical packs should specify measurements from fixed points (center front, shoulder seam).

Direct Answers to Sweatshirt Manufacturing Queries

"Where can I order custom sweatshirts?"

Custom sweatshirts are ordered directly from manufacturing partners like Athleisure Basics who specialize in cut-and-sew production combined with decoration capabilities. The commercial process requires your design specifications, fabric preferences (French terry, fleece, weight), decoration requirements, and quantity targets. We produce everything from basic crewnecks to fashion-forward silhouettes with integrated embroidery solutions.

"What is the best source for embroidered sweatshirts in Portugal?"

Portugal offers exceptional manufacturing sources for embroidered sweatshirts, particularly factories with vertically integrated capabilities. The optimal partners provide: digital embroidery expertise across multi-head machines, fabric sourcing knowledge for optimal embroidery substrates, structured quality control systems, and ethical production standards. Our Portugal-based facility combines traditional textile craftsmanship with modern technology specifically for premium embroidered sweatshirt production.

"Who can manufacture low MOQ sweatshirts with embroidery?"

We specialize in low MOQ embroidered sweatshirt manufacturing starting from 50 pieces per style. This enables brands to develop small collections, test market response, or create limited editions without significant inventory commitment. Our production process includes professional digitizing, physical sampling for approval, and scalable manufacturing that maintains industrial quality standards regardless of batch size.

"How much are custom embroidered sweatshirts in Portugal?"

Custom embroidered sweatshirts manufactured in Portugal typically range from €18-€55 per piece for MOQs of 50-100 units. Price variables include: sweatshirt construction (French terry vs. fleece, 280GSM vs. 350GSM), embroidery complexity (stitch count, color changes), and fabric quality. Basic crewnecks with simple chest embroidery start at the lower range, while heavyweight fashion sweatshirts with complex multi-technique designs approach higher price points.

Integrating Embroidery into Product Development Workflow

- Collection Planning: Align embroidery development with seasonal calendars. Factor digitizing and sampling time (2-3 weeks) into critical path.

- Costing Integration: Include digitizing fees and per-unit embroidery costs in overall garment costing. Complex back designs cost 2-3x more than simple chest logos.

- Technical Documentation: Create embroidery specification sheets including: approved stitch file name, Pantone thread colors, placement coordinates, and reference images.

- Sampling Protocol: Never proceed without physical samples. Evaluate stitch quality, thread sheen, fabric interaction, and overall hand-feel.

- Production Coordination: Confirm embroidery capacity and timeline alignment with cut-and-sew production for seamless workflow integration.

Optimizing Design Communication with Manufacturing Partners

- Provide Vector-Only Artwork: .AI or .EPS files with outlined fonts and clean paths.

- Include Technical Mockups: Show placement, size dimensions, and specify which elements use special techniques (puff, appliqué).

- Color Specification: Use Pantone (PMS) codes for thread color matching, not RGB/CMYK values.

- Reference Existing Samples: Share examples of embroidery styles you admire for technical reference.

- Request Feasibility Feedback: Before finalizing designs, consult with digitizing specialists on detail preservation at intended size.

For a comprehensive understanding of custom hoodie production, explore our detailed guide: Custom Embroidered Hoodies: A Complete Manufacturing Guide.

Structured FAQ for Embroidered Sweatshirt Production

Section 1: Design & Application

Q: What's the practical difference between embroidered sweatshirts and embroidered hoodies?

A: The primary difference is the garment structure: sweatshirts typically feature crewneck construction without hoods, while hoodies include hoods and often front pockets. Embroidery considerations are largely similar, though hoodies offer additional placement options (hood panels). Sweatshirts generally present a cleaner canvas for centered designs and are perceived as slightly more elevated in certain contexts.

Q: Can you create photorealistic embroidery from photographs?

A: Embroidery is not ideal for photorealistic reproduction. The technique creates images with solid color areas and texture, not smooth gradients. Photographs must be heavily stylized, simplified, and converted to limited color palettes for digitizing. For true photographic detail, direct-to-garment (DTG) printing is more suitable, though embroidery can create striking interpretive versions with distinct textural character.

Q: What defines a "monogrammed sweatshirt" in commercial production?

A: A commercial monogrammed sweatshirt features interlocked or combined letters (typically initials) created as a single embroidered unit. Production involves digitizing the letter combination with elegant satin stitches, often in script or decorative fonts. Placement is usually left chest or sleeve, conveying personalized, classic sophistication. Minimums typically follow standard embroidery MOQs (50+ pieces).

Section 2: Technical Execution

Q: Where is the optimal placement for embroidery on sweatshirts?

A: Optimal placement depends on design and commercial intent. Left chest (3-4" from center) is classic for logos. Center chest accommodates larger statements (6-8" wide). Sleeve placement (shoulder area) works for secondary branding. Full back (10-12" wide) maximizes impact for elaborate designs. Consider your audience and styling context when deciding.

Q: How do I choose between flat and 3D puff embroidery for my design?

A: Choose flat embroidery for detailed designs, text requiring legibility, and polished aesthetics. Choose 3D puff to add physical dimension and tactile emphasis to bold shapes, outlines, or simple graphic elements. Puff is less effective for fine details under 0.5cm. Many commercial designs combine both: puff for outlines, flat for fills.

Q: What are practical size limits for sweatshirt embroidery?

A: Machine hoops typically accommodate up to 12" x 12" designs, but practical sweatshirt limits consider garment construction. Maximum recommended back designs are 10" wide to avoid side seams. Chest designs optimally range 3-8" wide. Sleeve designs are typically 2-4" wide. Exceeding these requires specialized hooping and may affect garment drape.

Section 3: Commercial Production

Q: Can I get samples with different embroidery placements before bulk order?

A: Yes, placement sampling is standard in commercial development. You can request 2-3 placement options for evaluation. Each distinct sample incurs sampling costs (digitizing if different, production, shipping) but provides valuable visualization before committing to bulk production quantities.

Q: How does embroidery affect overall production lead time?

A: Embroidery adds 1-2 weeks to standard garment production time. After cut-and-sew completion, embroidery requires: machine setup and testing, production running time (depending on stitch count and quantity), trimming, and inspection. Complex designs with high stitch counts (15,000+) or multiple locations significantly increase time requirements.

Q: Do you provide design concept development services?

A: As a manufacturing specialist, our expertise focuses on production execution and technical optimization. We recommend working with a graphic designer to finalize concepts into production-ready vector files. We then provide technical feedback on feasibility, suggest optimizations for embroidery, and handle digitizing and production execution from approved artwork.

Leave a comment

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.